Prototyping

Prototyping is an essential process in industrial product development that involves the production and testing of preliminary versions of a product. This approach enables companies to test ideas quickly and cost-effectively, identify errors early and continuously improve the design. By using the latest technologies such as 3D printing, CNC milling and virtual simulations, prototypes can be created with precision and detail. Prototyping promotes innovation and competitiveness by shortening the development cycle and ensuring that the final products meet both functional requirements and quality standards. In an age where speed and flexibility are crucial, prototyping has become an indispensable part of industry.

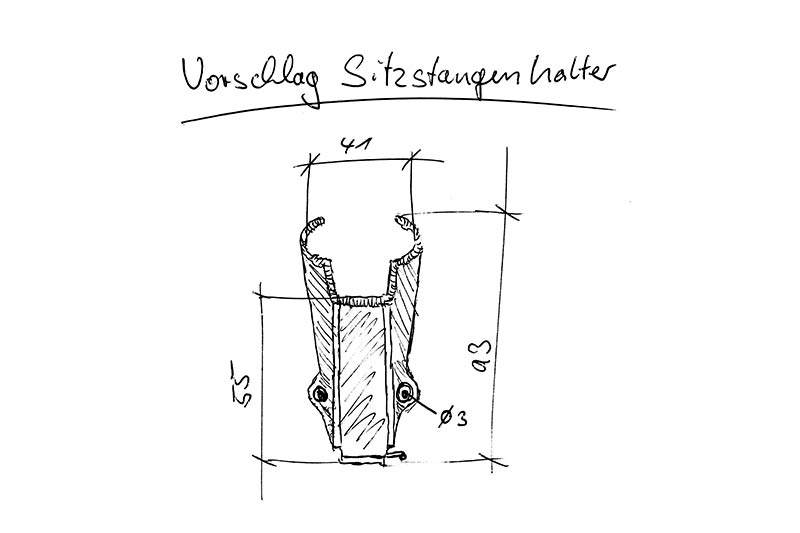

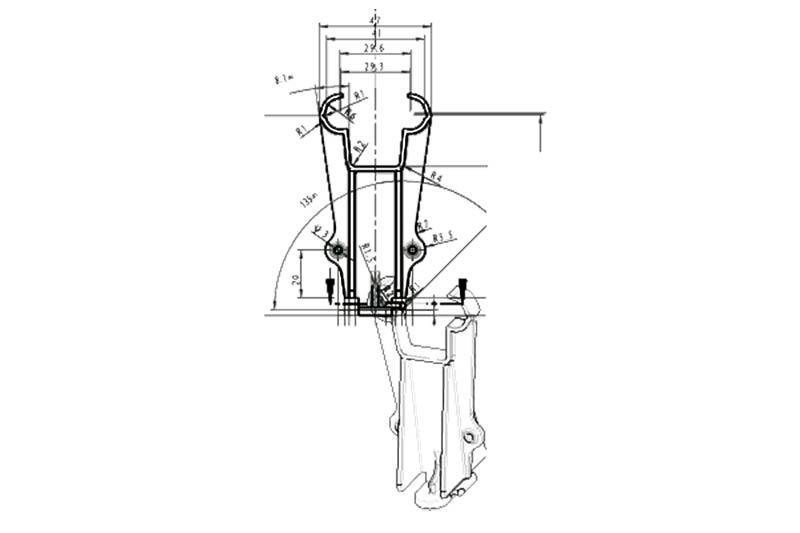

In addition to the various options for an initial visualization of the component, an indispensable part of component development today is an actual, further assessment and appropriate installation before the necessary series equipment is created.

BARKU offers you as a customer a variety of quick and flexible options "in-house" depending on your requirements. Starting with the "simple" filament-printed part as a purely visual object through to the precision sample part in the STL (stereolithography) process. For smaller pilot series, we offer you initial components in the vacuum casting process. And of course there is also the option of validating the article function using the classic use of a pre-series tool with series-identical materials.