Toolmaking

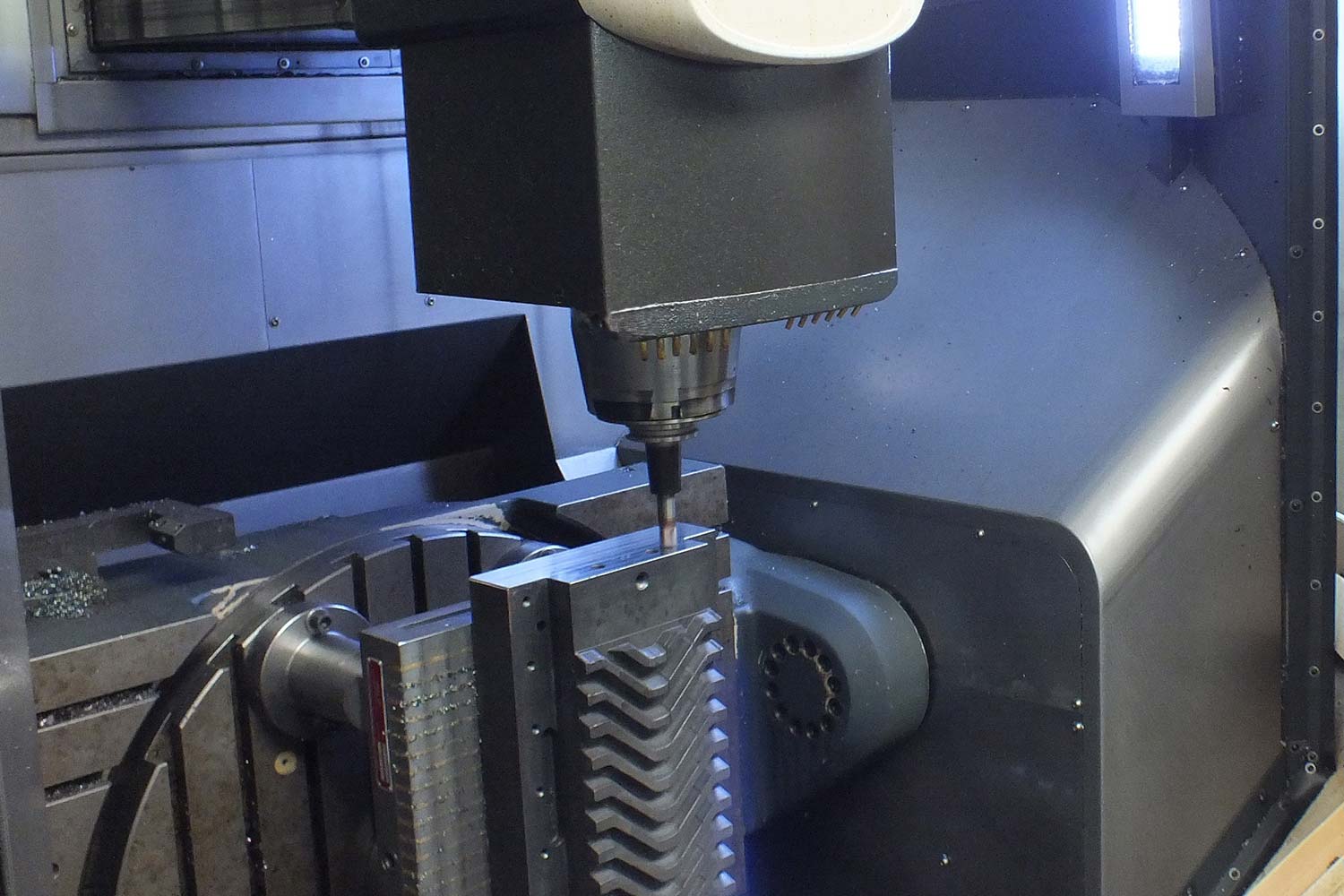

Toolmaking is a core discipline in industrial manufacturing that specializes in the design and manufacture of molds needed to produce components and end products. These include molds, templates, punching and bending devices used in various manufacturing processes. Precision and quality in toolmaking are crucial as they directly affect the efficiency and accuracy of production lines. Modern techniques such as CNC machining, 3D printing and computer-aided design (CAD) have revolutionized toolmaking by reducing development times and increasing the complexity and precision of the tools produced.